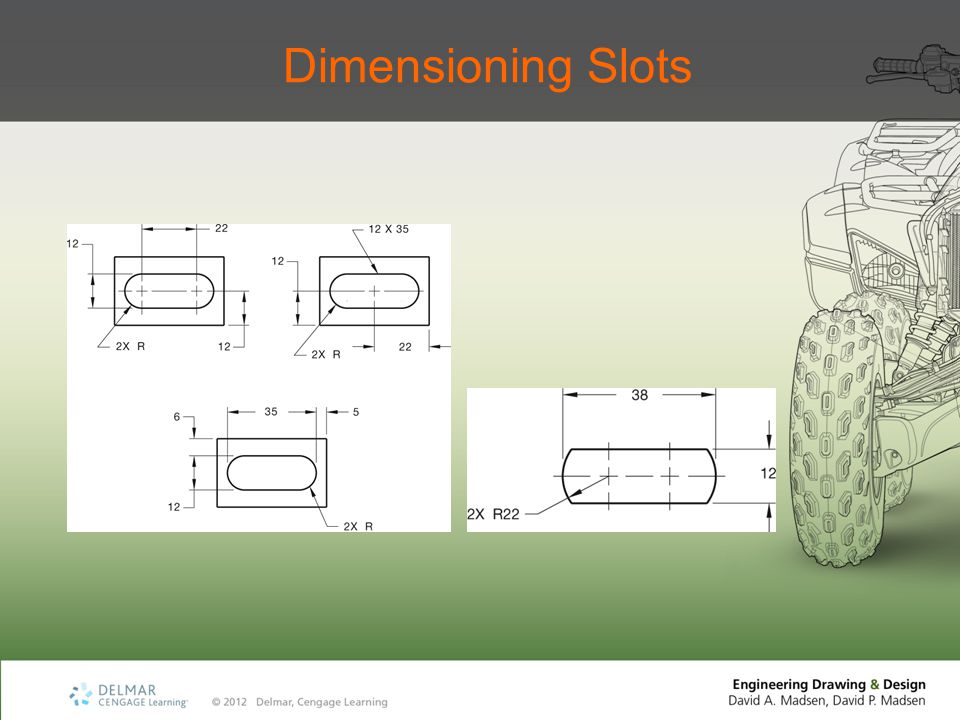

Dimensioning A Slot Pattern

This information applies to the American Steel Industry.

Holes and Slots

Standard Holes

- Common pipesizes and slot configurations are shown, other sizes up to 48', SCH or SDR'S and slot patterns are available upon request. Slot spacing and slot length is nominal, small variances may occur due to ovality of pipe and the effects of temperature. 14 1/2' 11 3/4'.375' 9 1' 5 2' 3.5 3' 2 6'.

- Within the Pattern command we are able to increment a feature through the spacing or size, we can control this using a dimension and even override individual instances. In this example we have a slot located on the origin and created a linear pattern going vertically above with 8 instances.

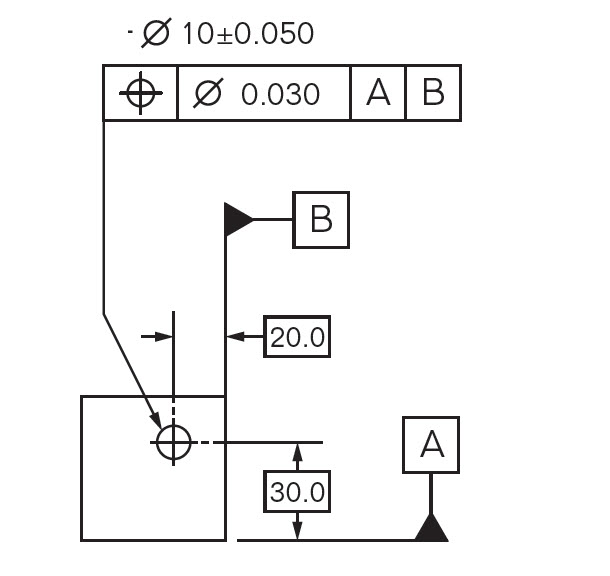

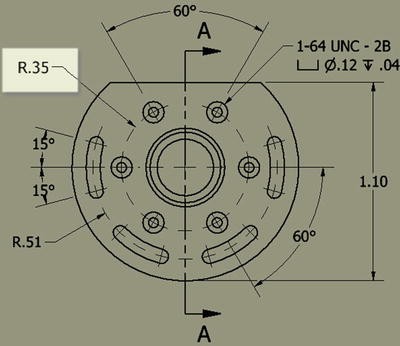

- . Circular hole patterns may be defined with polar coordinate dimensioning. When possible, dimension angles in degrees and decimal parts of degrees. Base dimensions at the mean of a tolerance because the computer numerical control (CNC) programmer normally splits a tolerance and works to the mean. While this is theoretically desirable.

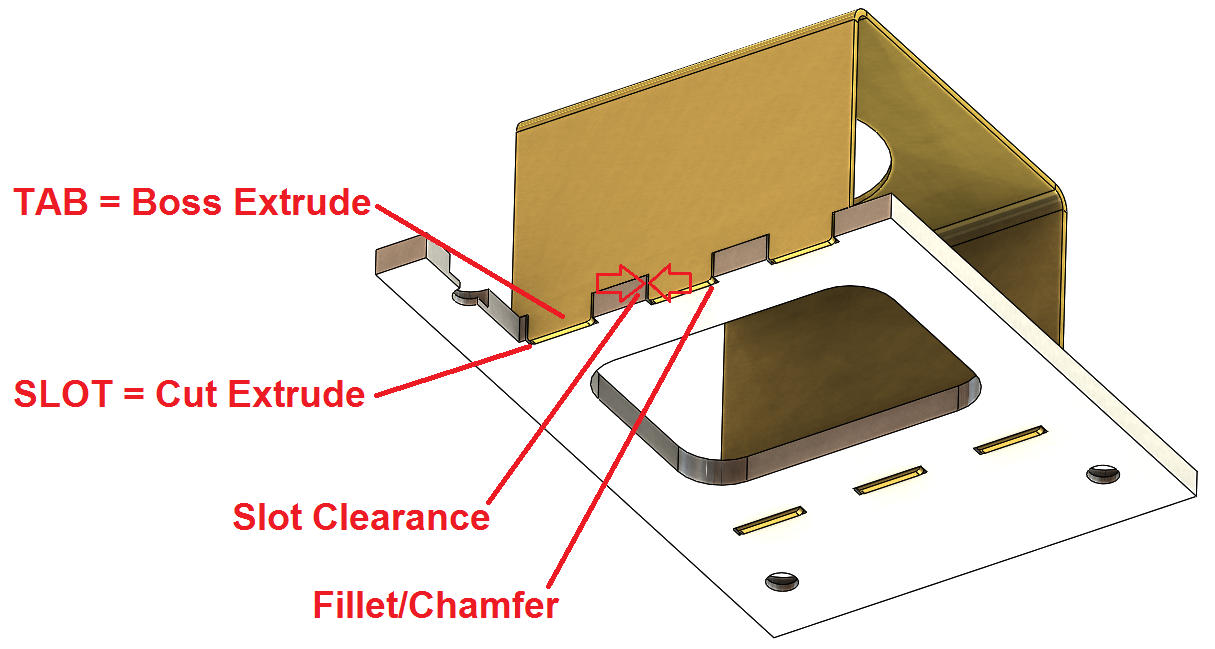

- Slots Slotted series of channels offer full flexibility. A variety of pre-punched slot patterns eliminate the need for precise field measuring for hole locations. Slots offer wide adjustments in the alignment and bolt sizing. Holes A variety of pre-punched 9/16” (14.3 mm) diameter hole patterns are available in our channels.

The correct calculated values are 2.962 and.976 instead of the 2.972 and.986Quickly shows how to use GD&T to locate and size 'slots' or 'slotted holes' in.

Standard hole sizes for bolts are made 1/16-in. larger in diameter than the nominal size of the fastener body. This provides a certain amount of play in the holes, which compensates for small misalignment’s in hole location or assembly, and aids in the shop and field entry of fasteners. In the absence of approval by the engineer for use of other hole types, standard holes shall be used in high strength bolted connections.

Although most holes for high-strength bolts are made 1/16-in. larger in diameter than the bolt body, certain conditions encountered in field erection require greater adjustment than this clearance can provide and approval from the engineer is required.

The maximum sizes of holes for bolts are given in the table below, except that larger holes, required for tolerance on location of anchor bolts in concrete foundations, are permitted in column base details.

Standard holes shall be provided in member-to-member connections, unless oversized, short-slotted or long-slotted holes in bolted connections are approved by the designer. Finger shims up to 1/4-in. may be introduced into slip-critical connections designed on the basis of standard holes without reducing the allowable shear stress of the fastener.

Oversize and Slotted Holes

When approved by the engineer, oversize, short slotted holes or long slotted holes may be used subject to the following joint detail requirements:

(1) Oversize holes may be used in any or all plies of connections in which the allowable slip resistance of the connection is greater than the applied load. Oversized holes shall not be used in bearing-type connections. Hardened washers shall be installed over oversized holes in an outer ply.

(2) Short slotted holes may be used in any or all plies of connections designed on the basis of allowable stress on the fasteners provided the load is applied approximately normal (between 80 and 100 degrees) to the axis of the slot. Short slotted holes may be used without regard for the direction of applied load in any or all plies of connections in which the allowable slip resistance is greater than the applied force. Washers shall be installed over short-slotted holes in an outer ply; when high strength bolts are used, such washers shall be hardened.

(3) Long slotted holes may be used in one of the connected parts at any individual faying surface in connections designed on the basis of allowable stress on the fasteners provided the load is applied approximately normal (between 80 and 100 degrees) to the axis of the slot. Long slotted holes may be used in one of the connected parts at any individual faying surface without regard for the direction of applied load on connections in which the allowable slip resistance is greater than the applied force. Where long-slotted holes are used in an outer ply, plate washers or a continuous bar with standard holes, having a size sufficient to completely cover the slot after installation, shall be provided. In high-strength bolted connections, such plate washers or continuous bars shall not be less than 5/16-in. thick and shall be of structural grade material, but not be hardened. If hardened washers are required for use of high-strength bolts, the hardened washers shall be placed over the outer surface of the plate washer or bar.

(4) Fully inserted finger shims between the faying surfaces of load transmitting elements of connections are not to be considered a long slot element of a connection.

Nominal Hole Dimensions

Anchor Bolt Holes

Hole sizes for steel-to-steel structural connections are not the same as hole sizes for steel-to-concrete anchorage applications. In the case of steel-to-steel connections, the parts are made in a shop under good quality control, so standard holes (bolt diameter plus 1/16″), oversized holes (bolt diameter plus 3/16″), and short and long-slotted holes can be used quite successfully. However, the field placement of anchorage devices has long been subject to more permissive tolerances (and often, inaccuracies that exceed those tolerances anyway and may require consideration by the structural Engineer of Record).

AISC published Steel Design Guide Series 1, Column Base Plates back in the early 1990s. At that time, it was recognized that the quality of foundation work was getting worse and worse. To allow the erector (and designer) greater latitude when possible, the permissible hole sizes in base plates were increased. These same larger hole sizes were included in the 2nd ed. LRFD Manual. The values there are maximums, not a required size. Smaller holes can be used if desired. Plate washers are generally required with these holes because ASTM F436 washers can collapse into the larger-sized holes, even under erection loads.

The larger hole sizes are primarily intended for the majority of base plates that transfer only axial compression from the column into the foundation. The anchor rods don’t usually do much after erection in that case.

To allow for misplaced bolts, holes in base plates are oversized. The AISC Manual of Steel Construction recommends the following oversized hole diameters for each bolt diameter:

Anchor Bolt Hole Dimensions

AISC, Steel Design Guide Series 1, Column Base Plates, suggests that using oversize holes meeting these criteria may still not accommodate field variations in anchor bolt placement and suggests adding 1/4 in. to the hole diameter listed. The guide recommends using a heavy plate washer over the holes. The AISC Structural Steel Educational Council cites the following example: “If bolts are misplaced up to 1/2 inch, the oversized base plate holes normally allow the base plate and column to be placed near or on the column line. If the bolts are misplaced by more than 1/2 inch, then corrective work is required.”

Based on AISC oversize holes, the AISC Structural Steel Educational Council recommendations, and concrete contractor anchor-bolt placement techniques, ASCC (American Society of Concrete Contractors) concrete contractors recommend the following tolerance for each bolt location:

- 3/4-in. and 7/8-in. diameter bolts: ±1/4 in.

- 1-in., 1-1/4-in., and 1-1/2-in. diameter bolts: ±3/8 in.

- 1-3/4-in., 2-in., and 2-1/2-in. diameter bolts: ±1/2 in.

End of article.

- Antenna Theory Tutorial

- Antenna Basic Terms

- Types of Antennas

- Antenna Arrays

- Wave Propagation

Dimensioning A Slot Pattern Set

- Antenna Theory Useful Resources

- Selected Reading

A folded dipole is an antenna, with two conductors connected on both sides, and folded to form a cylindrical closed shape, to which feed is given at the center. The length of the dipole is half of the wavelength. Hence, it is called as half wave folded dipole antenna.

Frequency range

The range of frequency in which half wave folded dipole operates is around 3KHz to 300GHz. This is mostly used in television receivers.

Construction & Working of Half-wave Folded Dipole

This antenna is commonly used with the array type antennas to increase the feed resistance. The most commonly used one is with Yagi-Uda antenna. The following figure shows a half-wave folded dipole antenna.

This antenna uses an extra conducting element (a wire or a rod) when compared with previous dipole antenna. This is continued by placing few conducting elements in parallel, with insulation in-between, in array type of antennas.

The following figure explains the working of a half-wave folded dipole antenna, when it is provided with excitation.

If the diameter of the main conductor and the folded dipole are same, then there will be four folded (two times of squared one) increase in the feed impedance of the antenna. This increase in feed impedance is the main reason for the popular usage of this folded dipole antenna. Due of the twin-lead, the impedance will be around 300Ω.

Dimensioning A Slot Pattern Block

Radiation Pattern

The radiation pattern of half-wave folded dipoles is the same as that of the half-wave dipole antennas. The following figure shows the radiation pattern of half-wave folded dipole antenna, which is Omni-directional pattern.

Half-wave folded dipole antennas are used where optimum power transfer is needed and where large impedances are needed.

This folded dipole is the main element in Yagi-Uda antenna. The following figure shows a Yagi-Uda antenna, which we will study later. The main element used here is this folded dipole, to which the antenna feed is given. This antenna has been used extensively for television reception over the last few decades.

Advantages

The following are the advantages of half-wave folded dipole antenna −

Reception of balanced signals.

Receives a particular signal from a band of frequencies without losing the quality.

A folded dipole maximizes the signal strength.

Disadvantages

The following are the disadvantages of half-wave folded dipole antenna −

Displacement and adjustment of antenna is a hassle.

Outdoor management can be difficult when antenna size increases.

Applications

The following are the applications of half-wave folded dipole antenna −

Mainly used as a feeder element in Yagi antenna, Parabolic antenna, turnstile antenna, log periodic antenna, phased and reflector arrays, etc.

Generally used in radio receivers.

Most commonly used in TV receiver antennas.